Simulating is more important than philosophising: The article explores the question of whether gap pads are always the panacea for the thermal design of electronic products. What are the influencing factors?

As an applications engineer, I hear time and again when it comes to the thermal design of electronic products: “we want to avoid air pockets” or “we want the right gap pad for each application”.

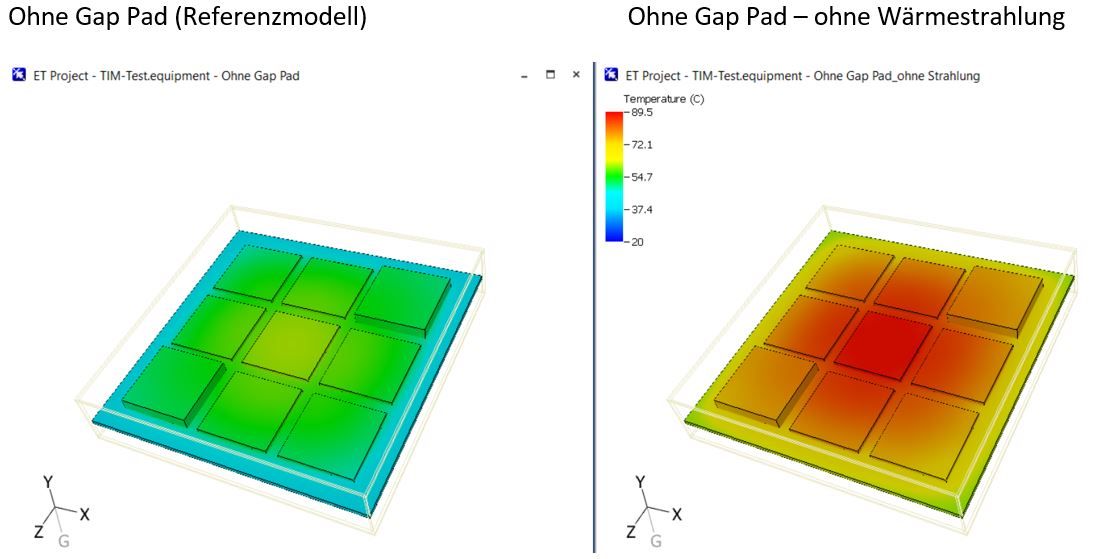

Air is a good insulator. But does an additionally used component, which usually does not conduct heat very well either, really always bring better results? Mathematically this is clear and logical, but then only the one heat path, heat conduction, is taken into account. To what extent do convection and thermal radiation also contribute to cooling? This article is intended to answer these questions.

Thermal Interface Material – or better: Air Displacement Material

Gap pads belong to the group of TIMs (Thermal Interface Materials). TIMs are available, for example, as pastes, adhesives, films, phase change materials or pads. Depending on the application, either one or the other is more suitable. Pastes are usually used to bridge a few µm. Gap pads are needed for larger gaps in the mm range. A TIM is basically an additional component that is not involved in the function of the electrical device.

These materials are only used to fill the air-filled gap of an electrical component (a power dissipator) towards a cooling surface with the aim of improving its heat dissipation. With a thermal conductivity of approx. 0.026 W/(mK), air is one of the worst “materials” for this task.

Would you like to read more about this article?

You can find this article in our company channel in Elektronikpraxis magazine – Link